coenzyme q10 recommended dosage

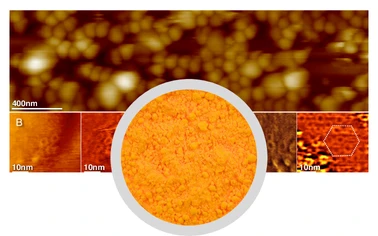

/Introduction to Coenzyme Q10 Raw Material for B2B Applications In the rapidly evolving nutraceutical and cosmeceutical sectors, the demand for high-purity, bioavailable active pharmaceutical ingredients (APIs) is paramount. Among these, Coenzyme Q10 CoQ10 Powder Raw Material Cardiovascular Health Antioxidant Skin Care stands out as a critical ingredient. Known for its indispensable role in cellular energy production, potent antioxidant properties, and significant health benefits, CoQ10 is increasingly integrated into advanced formulations targeting cardiovascular support, cellular health, and dermatological applications. This comprehensive overview provides B2B decision-makers and technical engineers with an in-depth understanding of the product’s manufacturing, technical specifications, market trends, and strategic advantages. The market for CoQ10 raw material is driven by a global surge in health awareness, an aging population, and a heightened focus on preventive medicine. Its versatility across pharmaceuticals, dietary supplements, and cosmetic products underscores its value proposition for manufacturers seeking to deliver science-backed solutions. Industry Trends and Market Dynamics The global CoQ10 market is projected to grow significantly, with a CAGR estimated at around 7-9% from 2023 to 2030, driven by its expanding applications. Key trends include: Increased Demand for Bioavailable Forms: Consumers and formulators are increasingly seeking enhanced absorption CoQ10, leading to innovations in delivery systems like liposomal CoQ10 and micronized powders. Expansion in Functional Foods & Beverages: Beyond supplements, CoQ10 is being incorporated into functional foods and beverages for convenient consumption. Cosmeceutical Boom: The anti-aging and antioxidant properties of CoQ10 are fueling its growth in skincare, particularly in serums, creams, and lotions. Cardiovascular Health Focus: With rising incidences of cardiovascular diseases, CoQ10 remains a cornerstone ingredient for heart health supplements, often combined with omega-3s or magnesium. Regulatory Landscape: Stricter regulatory standards (e.g., FDA, EFSA) for purity and efficacy are influencing manufacturing practices and supplier selection. These trends underscore the importance of sourcing a high-quality Coenzyme Q10 CoQ10 Powder Raw Material Cardiovascular Health Antioxidant Skin Care that meets rigorous standards for purity, stability, and efficacy to capitalize on market opportunities. Manufacturing Process Flow The production of high-grade Coenzyme Q10 CoQ10 Powder Raw Material Cardiovascular Health Antioxidant Skin Care involves a sophisticated multi-stage biotechnological process, typically involving microbial fermentation followed by advanced purification. This ensures a product of exceptional purity and consistent quality, suitable for pharmaceutical and nutraceutical applications. Step 1: Microbial Fermentation Utilizing specialized microbial strains (e.g., Rhodobacter sphaeroides or other proprietary strains) in a controlled bioreactor environment. Glucose or other carbon sources, nitrogen sources, and trace minerals are precisely dosed. Temperature, pH, and dissolved oxygen are rigorously monitored to optimize CoQ10 biosynthesis. ↓ Step 2: Cell Harvest & Lysis Post-fermentation, microbial cells are harvested via centrifugation or filtration. The harvested biomass then undergoes cell lysis (e.g., mechanical disruption, enzymatic treatment, or solvent extraction) to release intracellular CoQ10. ↓ Step 3: Extraction & Crude Purification CoQ10 is a lipophilic compound, requiring solvent-based extraction (e.g., using hexane, acetone, or ethyl acetate) from the lysed cell mass. This crude extract then undergoes initial purification steps to remove major impurities, often involving precipitation and filtration. ↓ Step 4: Advanced Purification & Crystallization Multiple stages of chromatographic purification (e.g., column chromatography, high-performance liquid chromatography - HPLC) are employed to achieve high purity. Subsequent controlled crystallization steps yield the desired crystalline CoQ10 powder, ensuring specific polymorphic forms and particle size distributions. ↓ Step 5: Drying, Milling & Quality Control The purified CoQ10 crystals are dried under vacuum to remove residual solvents. If required for specific applications, the material may undergo micronization or fine milling to achieve a desired particle size. Throughout the process, stringent quality control tests (HPLC for purity, GC-MS for solvent residues, microbial limits, heavy metals, etc.) are performed according to ISO 9001 and GMP standards. ↓ Step 6: Packaging & Storage The final Coenzyme Q10 CoQ10 Powder Raw Material Cardiovascular Health Antioxidant Skin Care is packaged in hermetically sealed, light-resistant container111s under inert gas to prevent oxidation and maintain stability. Storage conditions are controlled to ensure product integrity and a prolonged service life, typically 2-3 years under specified conditions. This meticulous process ensures that the finished raw material meets the highest industry standards, delivering superior performance for various applications. Target industries include Pharmaceuticals, Nutraceuticals, Functional Foods, and Cosmetics. Technical Specifications and Quality Assurance Our Coenzyme Q10 CoQ10 Powder Raw Material Cardiovascular Health Antioxidant Skin Care adheres to stringent quality parameters, ensuring compliance with global regulatory requirements such as USP, EP, and JP. The following table outlines key specifications: Parameter Specification Test Method Assay (CoQ10 Content) ≥ 98.0% (Ubiquinone) HPLC Appearance Yellow to Orange-Yellow Crystalline Powder Visual Melting Point 48 - 52 °C USP <741> Particle Size (D90) Typically < 100 µm (Customizable) Laser Diffraction Loss on Drying ≤ 0.5% USP <731> Heavy Metals ≤ 10 ppm (Pb ≤ 1 ppm) ICP-MS Residual Solvents Complies with ICH Q3C (R5) GC-HS Microbiological Limits Complies with EP/USP Pharmacopoeial Methods Our commitment to quality is reinforced by certifications including ISO 9001:2015, FSSC 22000, HACCP, Halal, and Kosher. Each batch is subjected to rigorous testing to ensure purity, potency, and safety, providing our partners with the highest level of confidence in their formulations. Application Scenarios and Technical Advantages Application Scenarios: Cardiovascular Health Supplements: Integral to formulations for heart failure, hypertension, and statin-induced myopathy. CoQ10 supports mitochondrial function in cardiac cells, crucial for energy production. Antioxidant & Anti-Aging Products: Protects cells from oxidative stress by scavenging free radicals, preventing cellular damage. Used in dietary supplements and topical formulations for its broad spectrum antioxidant capabilities. Skin Care & Cosmeceuticals: Included in anti-wrinkle creams, serums, and sunscreens to promote skin rejuvenation, reduce UV damage, and enhance skin firmness. Its ability to penetrate the stratum corneum makes it highly effective. Energy & Vitality Supplements: As a key component of the electron transport chain, CoQ10 is essential for ATP synthesis, making it popular in supplements aimed at boosting energy levels and reducing fatigue. Neurological Health: Emerging research suggests a role in neuroprotection, applicable in supplements targeting cognitive function and neurodegenerative conditions. Technical Advantages: High Purity (≥ 98%): Ensures maximum active ingredient concentration, minimizing impurities that could affect product stability or efficacy. Optimal Particle Size Distribution: Our standard micronized grade improves dispersibility and dissolution rates, which are critical for enhancing bioavailability in oral formulations and uniform distribution in topical applications. Custom particle sizes are available. Excellent Stability Profile: Manufactured and packaged under controlled conditions to ensure exceptional oxidative stability, crucial for maintaining potency over shelf life, particularly in complex formulations. Superior Bioavailability (Proven): While a raw powder, its controlled particle morphology contributes to improved absorption kinetics when formulated into appropriate delivery systems (e.g., lipid-based formulations, emulsions). This allows for lower effective dosages compared to poorly processed CoQ10. Traceability & Compliance: Full traceability from raw material sourcing to final product, coupled with adherence to global pharmacopoeial standards (USP, EP, JP), mitigates regulatory risks for downstream manufacturers. Vendor Comparison and Customized Solutions Why Choose Our CoQ10 Raw Material? Selecting a reliable supplier for Coenzyme Q10 CoQ10 Powder Raw Material Cardiovascular Health Antioxidant Skin Care is crucial for product success. While many vendors offer CoQ10, our distinct advantages lie in our uncompromised commitment to quality, technical support, and flexible customization capabilities. Feature/Parameter Our Offering Typical Market Standard Assay Purity ≥ 98.0% (HPLC Verified) 97.0% - 99.0% (Varying test methods) Certifications ISO, FSSC 22000, HACCP, Halal, Kosher, GMP Often ISO, maybe GMP (fewer comprehensive certs) Particle Size Standard micronized (<100 µm), Customizable to specific D50/D90 Standard mesh size (e.g., 80-120 mesh), less fine control Bioavailability Support Enhanced material properties for improved absorption potential in final formulations Basic powder, requiring more complex formulation efforts Technical Support Dedicated R&D, formulation guidance, regulatory assistance Standard COA, limited technical consultation Customized Solutions: We understand that each application has unique requirements. Our team offers bespoke solutions for Coenzyme Q10 CoQ10 Powder Raw Material Cardiovascular Health Antioxidant Skin Care , including: Particle Size Optimization: Tailored micronization to achieve specific dissolution rates or dispersion characteristics for specialized formulations (e.g., sublingual, transdermal). Pre-mix Formulations: Development of custom CoQ10 blends with other active ingredients or excipients to streamline your manufacturing process. Enhanced Stability Variants: Options for specific coated CoQ10 or stabilized dispersions for sensitive applications. Specific Grade Development: Whether you require a food-grade, cosmetic-grade, or pharmaceutical-grade material with specific documentation. Application Case Studies Case Study 1: Enhanced Cardiovascular Supplement Formulation A leading nutraceutical company approached us seeking a high-purity CoQ10 powder with improved dispersibility for their next-generation cardiovascular health supplement. Their previous supplier's material had inconsistent particle size, leading to challenges in capsule filling and variable dissolution profiles. We provided our micronized Coenzyme Q10 CoQ10 Powder Raw Material Cardiovascular Health Antioxidant Skin Care with a tightly controlled D90 of less than 50 µm. Result: The customer reported a 15% improvement in capsule filling efficiency due to the superior flow properties and consistent bulk density of our CoQ10. In vitro dissolution tests confirmed a 20% faster release profile, indicating enhanced potential for bioavailability. This facilitated a successful product launch and positive feedback regarding product consistency. Case Study 2: Anti-Aging Serum Development A prominent cosmetic brand required a stable, highly dispersible CoQ10 raw material for a premium anti-aging facial serum. Their primary concern was ensuring the CoQ10 remained uniformly suspended in an emulsion, without degradation or sedimentation, and delivered effective antioxidant protection. We collaborated to supply a specialized grade of our CoQ10 powder, optimized for solubility in oil phases and stability against UV light, coupled with expert formulation advice. Result: The final serum formulation demonstrated exceptional stability over a 12-month shelf-life, with no noticeable CoQ10 degradation or phase separation. Consumer trials indicated visible improvements in skin texture and reduced appearance of fine lines within 8 weeks, attributed to the potent antioxidant effects of the CoQ10. This allowed the brand to launch a highly competitive product in the luxury skincare segment. Frequently Asked Questions (FAQ) Q: What is the primary difference between ubiquinone and ubiquinol CoQ10? A: Ubiquinone is the oxidized form of CoQ10, primarily involved in ATP production. Ubiquinol is the reduced, active antioxidant form of CoQ10, directly neutralizing free radicals. While ubiquinone must be converted to ubiquinol in the body to exert its antioxidant effects, our CoQ10 powder (ubiquinone form) is highly pure and effectively converted in healthy individuals. Ubiquinol forms are also available upon request for specific formulations requiring pre-converted CoQ10. Q: How does particle size impact the efficacy of CoQ10 raw material? A: Smaller, more uniform particle sizes (micronized powder) generally lead to improved dissolution rates and enhanced bioavailability for oral supplements. In topical applications, finer particles ensure better dispersion and absorption into the skin layers. Our customization options allow you to specify particle size for optimal performance in your final product. Q: What are your typical lead times for bulk orders of CoQ10 powder? A: Standard lead times for bulk orders (e.g., 50 kg to 500 kg) are typically 2-4 weeks after order confirmation and payment, depending on current stock levels and specific customization requirements. For larger volumes or expedited requests, please contact our sales team for precise scheduling. Q: Do you offer samples for R&D purposes? A: Yes, we provide samples of our Coenzyme Q10 CoQ10 Powder Raw Material Cardiovascular Health Antioxidant Skin Care for qualified B2B partners' research and development. Please contact our technical sales team with your specific requirements to arrange for sample delivery. Logistics, Warranty, and Customer Support Lead Time & Fulfillment: We maintain robust inventory levels and an efficient supply chain to ensure timely fulfillment of orders. For standard specifications, typical lead times are 14-28 days. For customized orders, lead times will be communicated upon detailed requirement assessment. Our global logistics network supports efficient delivery to your specified location, complete with necessary documentation for international trade and customs clearance. Warranty & Quality Commitment: Our Coenzyme Q10 CoQ10 Powder Raw Material Cardiovascular Health Antioxidant Skin Care is backed by a comprehensive warranty covering material purity, potency, and compliance with the Certificate of Analysis (CoA) for a period of 12 months from the date of shipment, provided it is stored and handled according to our recommendations. We guarantee that our products meet or exceed the specified technical parameters and all relevant international quality standards. Dedicated Customer Support: We offer unparalleled customer support, including: Technical Assistance: Our team of R&D scientists and technical experts is available to provide detailed product information, formulation guidance, and troubleshooting support. Regulatory Documentation: Comprehensive regulatory support, including dossiers, stability data, and compliance statements for various global markets (e.g., GRAS, Novel Food). Responsive Service: A dedicated account manager ensures prompt responses to inquiries and efficient processing of orders and technical requests. Contact us at sales@finutra.com or visit our website for more information on how we can support your business needs. References Langsjoen, P. H., & Folkers, K. (1993). Coenzyme Q10 in cardiovascular disease with special reference to congestive heart failure. Clinical Investigator, 71(8 Suppl), S165-S170. Pravst, I., Zmitek, K., & Zmitek, J. (2010). Coenzyme Q10 contents in foods and fortification strategies. Critical Reviews in Food Science and Nutrition, 50(4), 269-280. Inui, M., et al. (2008). Ubiquinol supplementation enhances antioxidant status and reduces muscle damage in competitive athletes. The FASEB Journal, 22(S1), 606.5. Snell, P. G., et al. (2008). Topical coenzyme Q10 for the management of fine lines and wrinkles. Journal of Cosmetic Dermatology, 7(S1), 125-130. DiMauro, S., & Schon, E. A. (2003). Mitochondrial DNA diseases. Molecular Genetics and Metabolism, 80(1-2), 1-13.

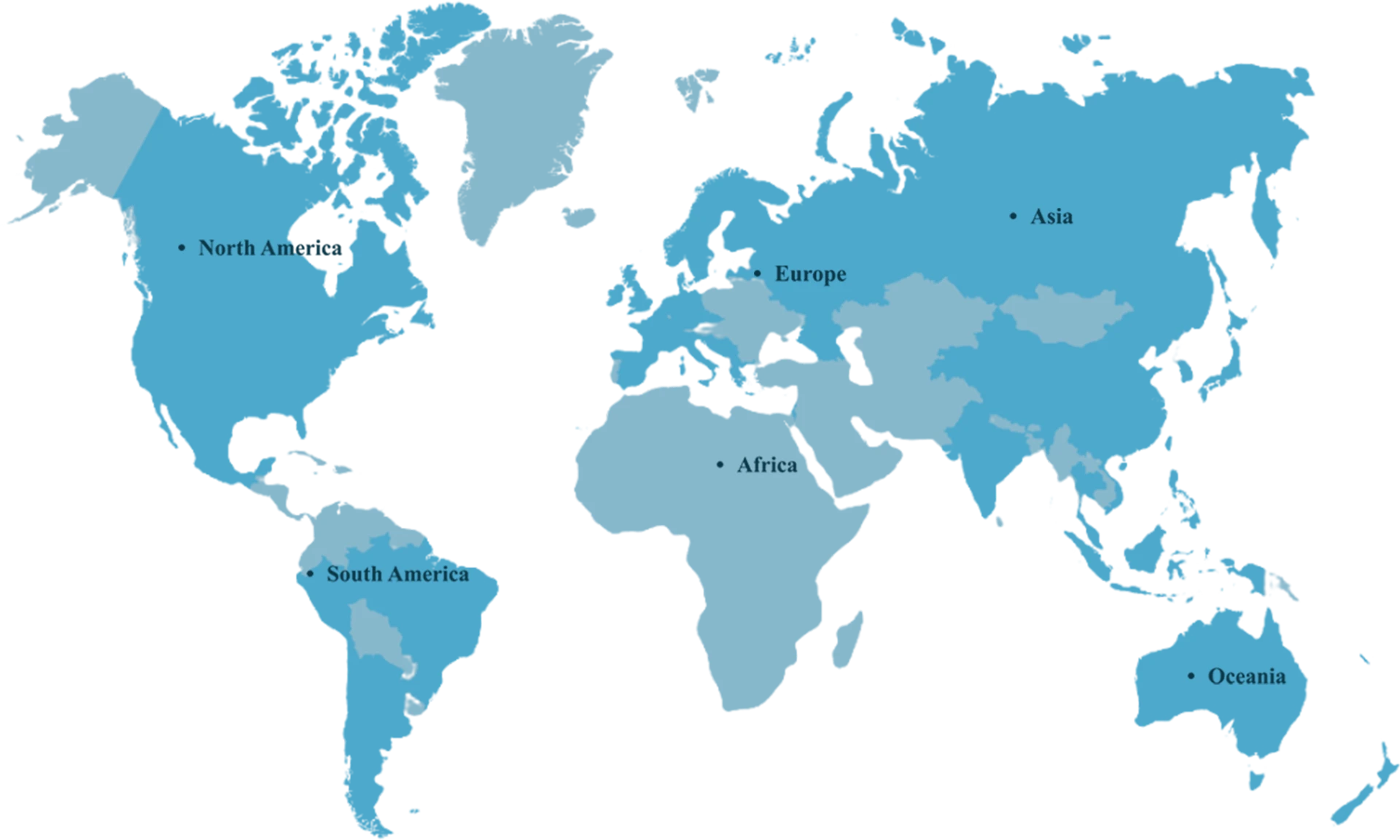

Finutra devotes to be an integrated supplier for global supply chain, we offer a

broad array of raw materials and functional ingredients

Authoritative Certification

Continuous Innovation, Customer First

Enhance core competitiveness to bring customers better products and services,

Each of these is the result of our team's relentless pursuit of excellence

and our deep commitment to social responsibility.

Global

Reach

FINUTRA has over 350,000 square feet of manufacturing and warehouse

space worldwide.

Industries We Serve

Advanced molecular distillation and microencapsulation

technology. Extremely bioavailable

trace carotenoids Intuitively soluble.

STAY UPDATED

Receive special offers and first look at new

products.

products.

Building 23B1, No.2 Yuanboyuan St., Zhengding Area of China (Hebei) Pilot Free Trade Zone

QUICK LINK

Finutra devotes to be an integrated supplier for global supply chain, we offer a broad array of raw

materials and functional ingredients as a manufacturer, distributor and supplier for global Beverage,

Nutraceutical, Food, Feed and Cosmeceutical.

Copyright © 2025 Hebei Finutra

Biotech Co.,

Ltd. All

Rights Reserved.

Privacy Policy